Introduction

Total Productive Maintenance (TPM) stands out as a pivotal Lean tool designed to optimize equipment effectiveness. By integrating maintenance into the daily operations of all employees, TPM transcends traditional maintenance boundaries, fostering a proactive culture aimed at preventing breakdowns and maximizing productivity.

History and Development

Tracing its roots to post-war Japanese industry, TPM was developed to reduce inefficiencies and waste in production. It has since evolved into a comprehensive operational approach, emphasizing preventative maintenance and involving all employees from the shop floor to management.

Key Principles

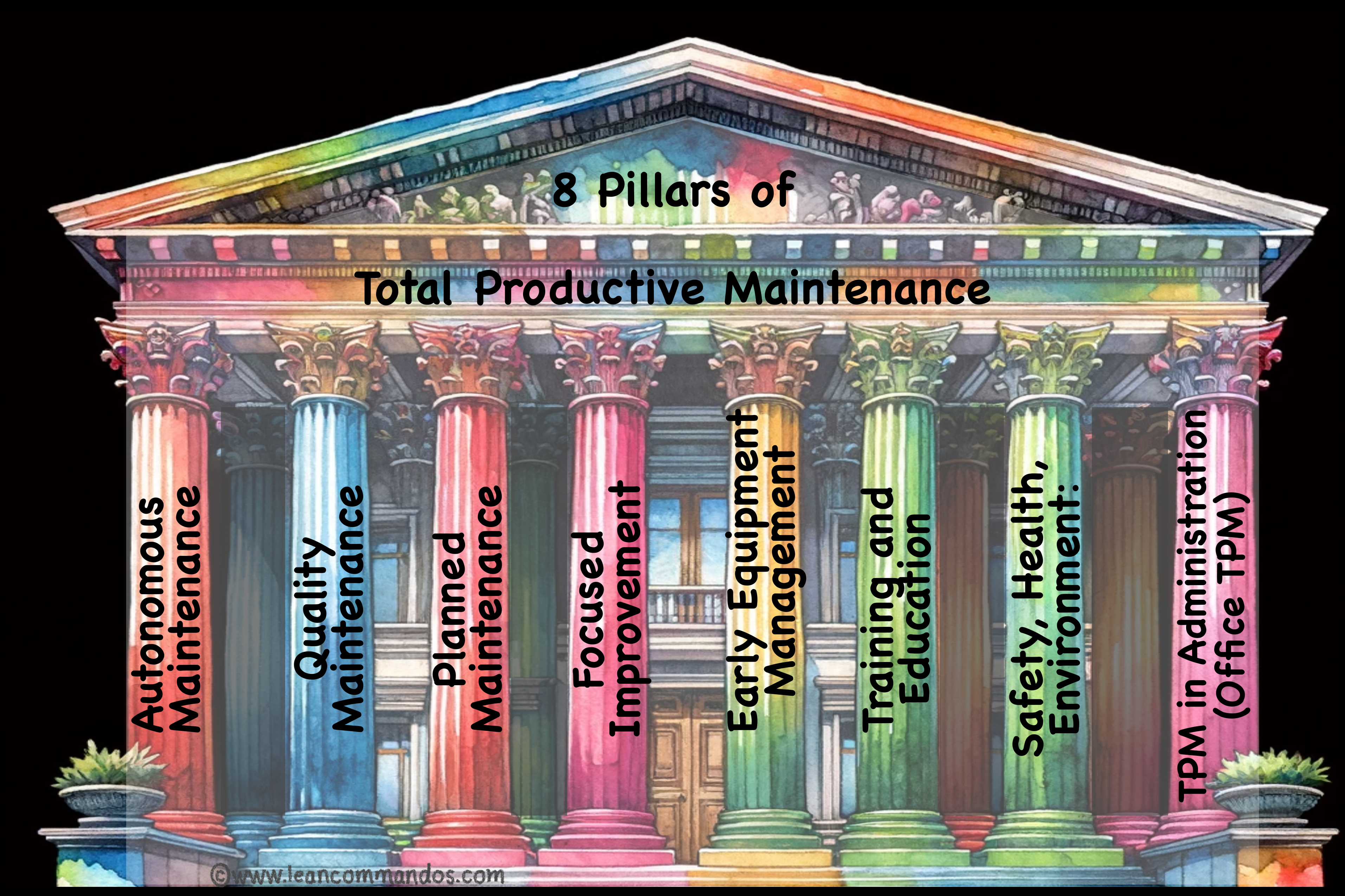

TPM is built on eight key pillars, including autonomous maintenance, planned maintenance, quality management, and focused improvement. These principles converge to eliminate the six big losses in production: breakdowns, set-up and adjustment losses, idling and minor stoppages, reduced speed, process defects, and reduced yield. The eight pillars of TPM are:

- Autonomous Maintenance (Jishu Hozen): Encourages operators to take responsibility for maintaining their equipment, with an emphasis on preventing rather than reacting to problems on the production line.

- Planned Maintenance: Scheduling maintenance tasks based on predicted and/or measured failure rates.

- Quality Maintenance (Hinshitsu Hozen): Aimed at eliminating product defects by managing equipment so that it is always in optimal operating condition

- Focused Improvement (Kobetsu Kaizen): Small groups of employees work together proactively to achieve regular, incremental improvements in equipment operation.

- Early Equipment Management: Directs practical knowledge and understanding of manufacturing equipment to achieve “design-in” maintenance for new equipment.

- Training and Education: Teaches employees how to use equipment properly and encourages the development of maintenance skills.

- Safety, Health, Environment: Focuses on creating a safe and healthy working environment for employees.

- TPM in Administration (Office TPM): Extends TPM beyond the production floor to all areas of the organization including administrative functions.

When to Use the Tool

Implement TPM when aiming to improve equipment reliability, production output, and quality. It’s particularly valuable in manufacturing settings with complex machinery but can be adapted to any operation where equipment efficiency is critical.

How It Works

Total Productive Maintenance (TPM) is not merely a maintenance strategy; it’s a transformative philosophy that integrates maintenance into the core of daily operations. To truly understand how TPM works, it’s essential to delve into its intricate mechanisms and methodologies, which empower organizations to maximize equipment effectiveness while minimizing downtime and waste.

1. Comprehensive Equipment and Process Audit:

Implementing TPM begins with a thorough assessment of existing equipment and processes. This audit serves as a baseline, identifying areas for improvement and gauging the overall health of the operation. Through this process, organizations can pinpoint inefficiencies, potential failure points, and opportunities for optimization.

2. Strategic Involvement of Team Members:

TPM operates on the principle of empowerment and engagement. Once areas for improvement are identified, a strategic plan is devised to involve all team members in the maintenance process. From frontline operators to management personnel, everyone plays a vital role in ensuring equipment reliability and performance.

3. Training and Empowerment:

Key to TPM’s success is the comprehensive training of all employees involved. Training programs are designed to impart the necessary skills and knowledge to identify potential issues before they escalate into critical failures. By empowering employees to take ownership of maintenance tasks, organizations foster a culture of accountability and proactivity.

4. Implementation of Autonomous Maintenance:

One of TPM’s fundamental pillars is autonomous maintenance, wherein frontline operators are empowered to conduct routine maintenance tasks on their equipment. This decentralization of maintenance responsibilities not only reduces the burden on dedicated maintenance personnel but also ensures that issues are addressed swiftly, minimizing downtime.

5. Continuous Improvement Through Kaizen:

TPM embraces the concept of Kaizen, or continuous improvement, as a core tenet. Teams are encouraged to regularly review processes, identify areas for enhancement, and implement incremental changes. By fostering a culture of continuous learning and adaptation, organizations can stay ahead of evolving challenges and maximize efficiency

6. Utilization of Performance Metrics:

Central to TPM implementation is the tracking and analysis of performance metrics. Key performance indicators (KPIs) such as equipment uptime, mean time between failures (MTBF), and mean time to repair (MTTR) provide valuable insights into the effectiveness of maintenance efforts. By leveraging data-driven insights, organizations can make informed decisions and drive continuous improvement initiatives.

7. Integration with Overall Business Objectives:

TPM is not an isolated initiative but rather a holistic approach that aligns with the broader business objectives. By integrating TPM goals with overarching business strategies, organizations ensure that maintenance efforts are in harmony with production targets, quality standards, and customer requirements.

In conclusion, Total Productive Maintenance (TPM) is a multifaceted approach that transcends traditional maintenance paradigms. By fostering a culture of proactive maintenance, empowerment, and continuous improvement, TPM empowers organizations to optimize equipment effectiveness, maximize productivity, and drive sustainable growth. Embracing TPM principles not only enhances operational efficiency but also cultivates a workforce that is engaged, empowered, and committed to excellence.

Benefits

Organizations embracing TPM can expect significant benefits including increased equipment uptime, reduced maintenance costs, improved product quality, and enhanced employee morale and job satisfaction.

Common Mistakes and Pitfalls

Common pitfalls in TPM implementation include insufficient training, lack of management support, resistance to cultural change, and the failure to track performance metrics. Avoiding these mistakes is crucial for TPM success.

Tips for Success

Successful TPM implementation relies on clear communication, comprehensive training, and continuous improvement. Management should lead by example, and incentives can be aligned with TPM goals to encourage team participation.

FAQs

What is the first step in starting TPM?

Begin with a thorough equipment and process audit to establish a baseline for improvement

Can TPM be applied to non-manufacturing environments?

Yes, while it originated in manufacturing, the principles of TPM can be applied to any operation with reliance on equipment.

How long does it take to see results from TPM?

Some improvements can be seen immediately, but significant results often require at least six months to one year of consistent practice.

Is TPM relevant for small-scale operations?

Absolutely, TPM is scalable and can deliver benefits to operations of any size

How does TPM differ from traditional maintenance?

TPM is a holistic approach that involves all employees in maintenance activities, not just maintenance personnel, and focuses on prevention rather than repair.

References and Further Reading

To deepen your understanding of TPM, consider these essential readings:

- “TPM in Process Industries” by Tokutaro Suzuki.

- “Introduction to TPM” by Seiichi Nakajima.

- “Total Productive Maintenance” by Terry Wireman.

Conclusion

TPM represents a transformative approach to maintenance and efficiency. By embracing its principles, organizations can reap the rewards of a more engaged workforce and streamlined operations.

3 Responses

I discovered your blog site on google and check a few of your early posts. Continue to keep up the very good operate. I just additional up your RSS feed to my MSN News Reader. Seeking forward to reading more from you later on!…

I really enjoy the article.Really looking forward to read more. Awesome.

Does your blog have a contact page? I’m having problems locating it but, I’d like to shoot you an e-mail. I’ve got some suggestions for your blog you might be interested in hearing. Either way, great website and I look forward to seeing it develop over time.