Introduction

Six Sigma is a powerful Lean management tool designed to minimize defects, enhance efficiency, and optimize processes across various industries. Its primary purpose lies in streamlining operations, reducing waste, and ultimately enhancing customer satisfaction.

History and Development

Originating from Motorola in the 1980s, Six Sigma has evolved into a comprehensive methodology embraced by organizations worldwide. It played a pivotal role in shaping Lean management strategies, emphasizing data-driven decision-making and continuous improvement.

Key Principles

Six Sigma operates on the principles of data analysis, process optimization, and rigorous problemsolving methodologies. It integrates statistical tools and techniques to identify and eliminate variations that lead to defects.

When to Use the Tool

Six Sigma operates on the principles of data analysis, process optimization, and rigorous problemsolving methodologies. It integrates statistical tools and techniques to identify and eliminate variations that lead to defects.

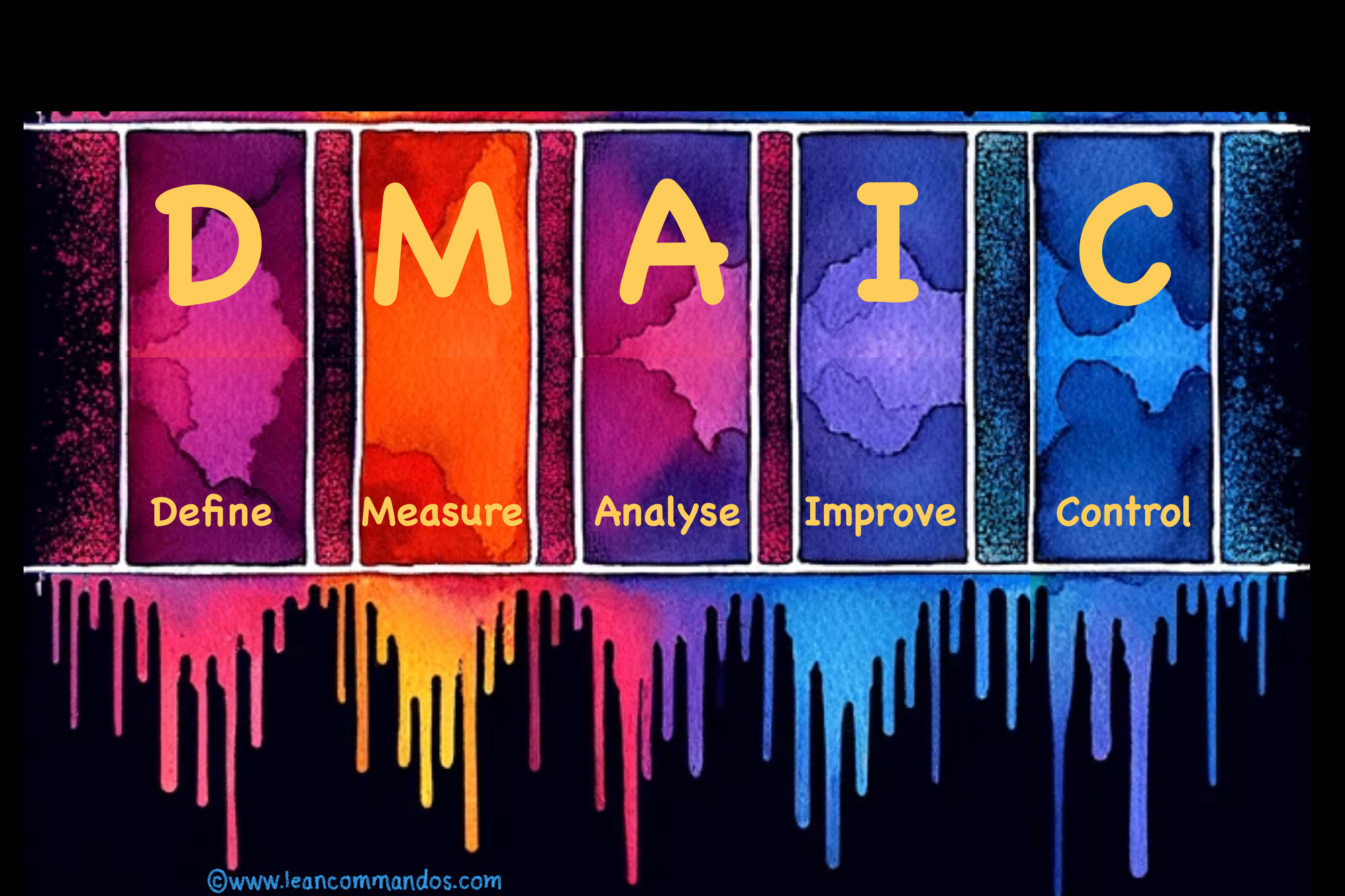

How It Works

Six Sigma operates as a systematic methodology aimed at achieving process perfection through a defined sequence of steps: Define, Measure, Analyze, Improve, and Control (DMAIC). This methodical approach ensures that organizations address issues with precision, focusing efforts on areas that directly impact quality, efficiency, and customer satisfaction.

1. Define:

The first step in the Six Sigma journey is to clearly define the problem, project goals, and customer requirements. This involves understanding the scope of the project, identifying stakeholders, and establishing measurable objectives. By defining these parameters upfront, organizations can ensure alignment and clarity throughout the improvement process.

2. Measure:

Once the problem is defined, the next step is to gather relevant data to quantify the current process performance. This involves identifying key metrics, collecting data points, and establishing baseline performance levels. Through rigorous measurement and analysis, organizations can gain insights into the current state of affairs and identify areas for improvement.

3. Analyze:

With data in hand, the focus shifts to identifying root causes of variations and inefficiencies using statistical methods. This phase often involves techniques such as regression analysis, hypothesis testing, and pareto analysis to uncover underlying issues impacting process performance. By dissecting data and pinpointing critical factors contributing to defects or deviations, organizations can develop targeted solutions for improvement.

4. Improve:

Armed with insights from the analysis phase, organizations can now implement solutions to address identified issues and optimize processes. This may involve redesigning workflows, standardizing procedures, or implementing technology-driven solutions to streamline operations. The key is to prioritize actions that deliver the most significant impact on quality and efficiency while aligning with the organization’s strategic objectives.

5. Control:

The final step in the DMAIC framework is to establish control mechanisms to sustain improvements and prevent regression. This involves developing monitoring systems, implementing standard operating procedures, and training personnel to ensure compliance with new processes. By instituting robust controls, organizations can safeguard against deviations and maintain the gains achieved through the Six Sigma initiative.

By following the DMAIC methodology, organizations can systematically tackle complex problems, drive continuous improvement, and achieve measurable results. Each phase of the Six Sigma process builds upon the previous one, creating a structured approach to problem-solving and process optimization. Through disciplined execution and a commitment to excellence, organizations can leverage Six Sigma to achieve operational excellence and deliver superior value to customers.

Benefits

Implementing Six Sigma yields numerous benefits, including enhanced product quality, reduced cycle times, increased productivity, and higher profitability. Moreover, it fosters a culture of continuous improvement and empowers employees to contribute to organizational success.

Common Mistakes and Pitfalls

Common challenges in Six Sigma implementation include insufficient management support, inadequate training, and resistance to change. Organizations should prioritize effective leadership, comprehensive training programs, and fostering a culture of collaboration to mitigate these pitfalls

Tips for Success

- Foster strong leadership commitment and involvement throughout the Six Sigma journey.

- Invest in comprehensive training programs to equip employees with necessary skills and knowledge.

- Encourage cross-functional collaboration to leverage diverse perspectives and expertise.

- Prioritize data-driven decision-making and continuous improvement initiatives.

Integration With Other Lean Tools

Six Sigma complements other Lean tools such as Kaizen, Lean manufacturing, and Value Stream Mapping. By integrating these methodologies, organizations can achieve synergistic effects and drive holistic process improvements

FAQs:

What is the difference between Lean and Six Sigma?

Lean focuses on eliminating waste and optimizing processes, while Six Sigma emphasizes reducing defects and variations.

Is Six Sigma only applicable to manufacturing industries?

No, Six Sigma principles are applicable across various industries, including healthcare, finance, and service sectors.

How long does it take to see results with Six Sigma implementation?

Results vary depending on the complexity of the project, but organizations often see significant improvements within a few months to a year.

Do I need specialized software for Six Sigma implementation?

While specialized software can streamline data analysis, it is not mandatory. Basic statistical tools like Excel can suffice for smaller projects.

How can I measure the success of Six Sigma initiatives?

Success can be measured through key performance indicators (KPIs) such as defect rates, cycle times, cost savings, and customer satisfaction scores.

Conclusion

Six Sigma stands as a cornerstone of Lean management, empowering organizations to achieve operational excellence and sustainable growth. By embracing its principles and methodologies, businesses can drive continuous improvement, enhance customer value, and thrive in today’s competitive landscape.

References and Further Reading

- “Lean Six Sigma: Combining Six Sigma Quality with Lean Production Speed” by Michael L. George

- “The Six Sigma Way: How GE, Motorola, and Other Top Companies are Honing Their Performance” by Peter S. Pande, Robert P. Neuman, and Roland R. Cavanagh

- “Six Sigma for Managers: 24 Lessons to Understand and Apply Six Sigma Principles in Any Organization” by Greg Brue

3 Responses

Very well written article. It will be beneficial to anybody who employess it, including myself. Keep doing what you are doing – can’r wait to read more posts.

Nice Post. It’s really a very good article. I noticed all your important points. Thanks.

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks