Introduction

One Piece Flow, a cornerstone of Lean manufacturing, focuses on the flow of products through the production process one at a time, minimizing work in progress (WIP) and enabling a smoother production system. This approach contrasts with traditional batch processing, where products are manufactured in large groups, leading to longer lead times and higher defect rates.

History and Development

The concept of One Piece Flow finds its roots in the Toyota Production System (TPS), where Taiichi Ohno, the system’s architect, emphasized its importance in reducing waste and improving productivity. This Lean tool has since been embraced across various industries, evolving from automotive manufacturing to healthcare and services.

Key Principles

The main principles of One Piece Flow are to produce what is needed when it’s needed and in the amount needed, thus emphasizing just-in-time production. It focuses on making one item at a time move through the production system without pauses, delays, or bottlenecks, which reduces lead time and inventory costs.

When to Use the Tool

One Piece Flow is most effective in a high-mix, low-volume production environment where flexibility is key, and in processes where reducing cycle time is crucial. It’s also applicable in settings that require high levels of quality and minimal defects.

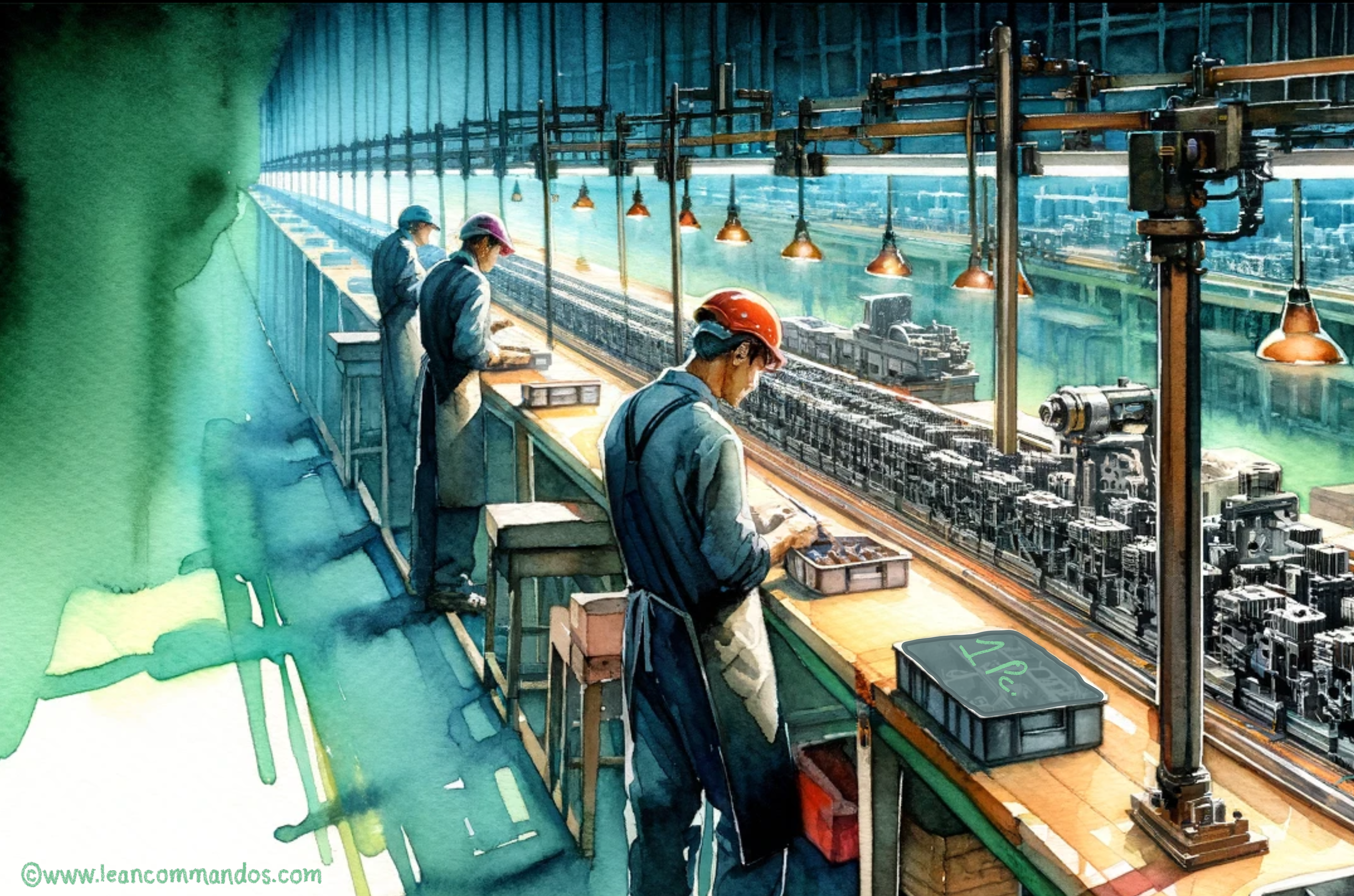

How It Works

Implementing One Piece Flow begins with the redesign of the production line. Instead of producing multiple parts before moving them to the next station, each product moves through each step of the process one by one. This requires a deep understanding of each step’s duration and a balance of workloads to avoid bottlenecks.

Firstly, map out the current process to identify each step and the time taken to complete it. This mapping should highlight any steps where delays or inventory build-up occur. The goal is to reorganize the workspace to ensure that each station is equipped to perform its task without waiting for the previous step to complete a batch. Workstations are often reconfigured into a U-shaped layout to facilitate easy handoffs and reduce movement.

Next, the production line is balanced. This involves allocating tasks so that each station has an equal amount of work, known as cycle time. Workers may need to learn multiple tasks to ensure flexibility and continuity of flow.

Tools like takt time are used to synchronize production with customer demand, ensuring that production matches the pace at which products must be completed to meet customer orders. If takt time is not considered, One Piece Flow could lead to overproduction.

The success of One Piece Flow depends on smooth transitions between tasks, clear communication, and consistent quality checks. Each piece is inspected as it passes from one stage to the next, allowing for immediate feedback and correction of defects, leading to a continuous improvement culture.

Benefits

One Piece Flow reduces cycle time, decreases WIP inventory, and minimizes the space required for production. It allows for immediate identification and correction of defects, thereby enhancing quality. The process also fosters employee engagement as workers gain a broader skill set by understanding the entire production flow.

Case Study

A renowned automobile manufacturer implemented One Piece Flow in one of their assembly lines. They restructured the production floor into a cell-based layout, trained workers to perform multiple tasks, and balanced the line to match takt time. The result was a 30% reduction in labor costs and a significant drop in the space required for production, demonstrating the tool’s efficacy in a real-world setting.

Common Mistakes and Pitfalls

Common mistakes in implementing One Piece Flow include failing to balance the line correctly, not training staff adequately, overlooking the importance of quality checks at each step, and not aligning production with real customer demand. These errors can lead to increased cycle times and reduced efficiency.

Tips for Success

For successful implementation, engage in thorough planning and employee training, balance the line to match takt time, ensure the quality at each step, and maintain flexibility to adapt to changes in demand. Continuous monitoring and improvement are also vital.

Integration With Other Lean Tools

One Piece Flow works synergistically with other Lean tools such as Kanban, to regulate the flow of materials; 5S, for workplace organization; and Kaizen, for continuous improvement.

FAQs

Can One Piece Flow be applied to service industries?

Yes, One Piece Flow can be adapted to service industries by streamlining processes to handle one transaction or customer at a time, reducing waiting times and improving service quality.

Is One Piece Flow suitable for every manufacturing environment?

While versatile, One Piece Flow is best suited for processes where the product variety is high and volumes are low to medium. High-volume, low-variety processes may benefit more from other Lean techniques.

How does One Piece Flow affect employee roles?

It typically requires workers to be cross-trained in multiple tasks, increasing their skillset and engagement.

Can One Piece Flow be implemented without automation?

Absolutely, One Piece Flow focuses on the process flowand is not dependent on technology, though technology can enhance its effectiveness.

How do you measure the success of One Piece Flow?

Success can be measured by improvements in key performance indicators like reduced cycle time, lower defect rates, decreased inventory levels, and increased customer satisfaction.

Other Lean Tools Used with One Piece Flow

One Piece Flow is often implemented alongside other Lean tools such as:

- Kanban: To control the workflow on the production floor.

- Jidoka (Autonomation): To automatically halt the production process when issues are detected.

- Total Productive Maintenance: To prevent equipment failure that could disrupt the flow.

References and Further Reading

For those looking to expand their knowledge on One Piece Flow and its applications, the following books are highly recommended:

- “The Toyota Way” by Jeffrey K. Liker: An in-depth look at the 14 management principles of theToyota Production System, including One Piece Flow.

- “Lean Thinking: Banish Waste and Create Wealth in Your Corporation” by James P. Womack and Daniel T. Jones: This book offers a comprehensive overview of the five Lean principles and their practical applications.

- “Learning to See: Value Stream Mapping to Add Value and Eliminate MUDA” by Mike Rother and John Shook: Although focused on Value Stream Mapping

By applying the principles of One Piece Flow, organizations can realize significant benefits in efficiency, quality, and employee satisfaction, making it a powerful tool in the Lean toolkit. Remember to customize the approach to your specific context and continuously seek improvements to ensure sustainable success.

5 Responses

You have made some really good points there. I looked on the net for more information about the issue and found most individuals will

go along with your views on this website.

Hey there! I know this is kinda off topic however , I’d figured I’d ask. Would you be interested in trading links or maybe guest authoring a blog article or vice-versa? My blog discusses a lot of the same topics as yours and I think we could greatly benefit from each other. If you happen to be interested feel free to shoot me an email. I look forward to hearing from you! Great blog by the way!

Major thanks for the post.Really thank you! Really Great.

I really lucky to find this internet site on bing, just what I was searching for : D besides saved to fav.

Magnificent beat ! I would like to apprentice while you amend your site, how can i subscribe for a blog site? The account helped me a acceptable deal. I had been a little bit acquainted of this your broadcast offered bright clear idea