Introduction

In the world of Lean management, 5S stands as a beacon of efficiency, a systematic approach to workplace organization that lays the groundwork for continuous improvement. This tool is not merely about cleanliness or organization; it is a pathway to transforming the culture of work environments, driving efficiency, safety, and a deep-seated operational excellence.

History and Development

Rooted in the Japanese manufacturing industry, the 5S system was popularized by Toyota in the 1970s as part of their Toyota Production System (TPS). It was a response to the need for quality, efficiency, and agility in production processes. The methodology has since transcended its industrial origins, proving its worth across various sectors by fostering a disciplined approach to workplace organization.

Key Principles

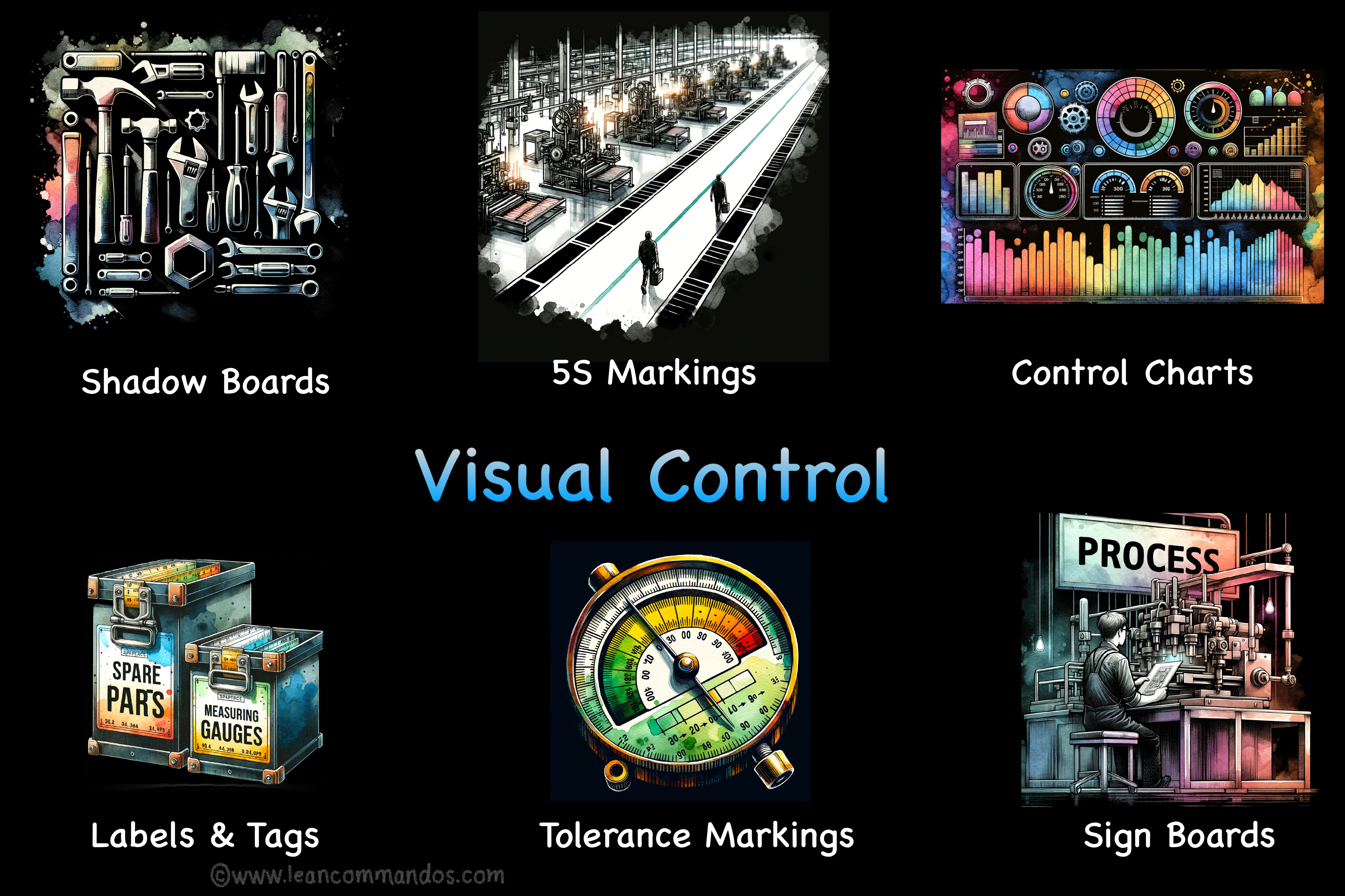

The essence of Visual Control lies in its simplicity: it utilizes visual signals to represent work status, standards, or problems. This could be as simple as color-coded areas, labels, signs, or even lights. The goal is to make the information easily accessible and understandable at a glance, minimizing errors and waste.

When to Use the Tool

Visual Control is most effective in environments where a quick dissemination of information is crucial to the operation. It’s ideal for managing workflow, ensuring safety, and maintaining high-quality standards. Whether on the manufacturing floor, in the emergency room, or within the software development cycle, Visual Control can be a game-changer.

How It Works

Implementing Visual Control begins with identifying the key processes and information that need to be communicated. For example, in a manufacturing setting, this could include production quotas, equipment status, or inventory levels.

The next step is to design visual cues that are intuitive and accessible. This often involves a collaborative process with the people who will use them daily. For instance, a red tag might indicate a defective part, while a green tag denotes one that’s passed inspection.

Visual Control boards are a common feature, displaying real-time data on key performance indicators (KPIs). These boards can show the day’s targets, current output, or any discrepancies. By placing these boards at strategic points, employees remain informed and can quickly adjust to changes or address issues.

Another facet of Visual Control is the use of outlines or shadows on workbenches to indicate where tools should be placed. This not only organizes the workspace but also highlights when a tool is missing, which could prevent a potential halt in the production line.

The overarching aim is to create a self-regulating environment where the status of the system is apparent to all. When an anomaly arises, it becomes immediately visible, prompting swift corrective action. This constant feedback loop is a form of Visual Control that drives continuous improvement and fosters a culture of collective accountability.

Benefits

Visual Control’s benefits are manifold. It enhances transparency, speeds up decision-making, improves safety, and fosters a proactive approach to problem-solving. Ultimately, it leads to higher productivity and better quality products or services.

Common Mistakes and Pitfalls

The most common mistakes in Visual Control implementation include overcomplicating the visuals, not involving team members in the design process, and failing to update the visuals when processes change. Avoiding these pitfalls is essential for the successful adoption of Visual Control.

Tips for Success

To succeed with Visual Control, engage your team in the creation of visuals, keep the designs simple and intuitive, and regularly review and update them to ensure they remain relevant and effective.

Integration With Other Lean Tools

Visual Control complements other Lean tools like 5S for workplace organization, Kanban for inventory management, and Andon for real-time alerting of issues. Together, these tools create a robust system for managing operations.

FAQ

Can Visual Control be used in non-manufacturing environments?

Absolutely. Visual Control is versatile and can be adapted to any industry, including healthcare, IT, and services

How often should Visual Control tools be updated?

Visual Controls should be reviewed regularly and updated whenever there are changes in processes, standards, or when feedback indicates a need for improvement.

Do Visual Controls need to be physical, or can they be digital?

They can be both. Digital dashboards are increasingly common, especially in fields like software development and logistics.

Is training required for implementing Visual Control?

While Visual Control is intuitive, some training on the specific symbols and boards used in an organization is beneficial.

How do you measure the effectiveness of Visual Control?

Measure the reduction in errors, improvements in efficiency, and check for increased adherence to standards.

References and Further Reading

For further reading on Visual Control, consider the following top 3 books:

- “Lean Thinking: Banish Waste and Create Wealth in Your Corporation” by James P. Womack and Daniel T. Jones.

- “The Toyota Way:14 Principles of Lean Thinking” by Jeffrey K. Liker.

- “Learning to See: Value Stream Mapping to Add Value and Eliminate MUDA” by Mike Rother and John Shook.

These works offer in-depth insights into Lean methodologies and provide further context for the practical application of Visual Control within various sectors.

Conclusion

Visual Control stands as a testament to the power of simplicity in Lean management. By harnessing the potential of visual cues, organizations can drastically improve communication, eliminate waste, and pave the way for a more efficient, responsive, and safer workplace.

Remember, the effectiveness of Visual Control is not in the complexity of the visuals but in their clarity and the team’s ability to interpret them correctly and act swiftly. When implemented thoughtfully, Visual Control is not just a Lean tool; it’s a beacon that guides the entire organization towards operational excellence.

3 Responses

My coder is trying to persuade me to move to .net from PHP. I have always disliked the idea because of the costs. But he’s tryiong none the less. I’ve been using Movable-type on a variety of websites for about a year and am concerned about switching to another platform. I have heard good things about blogengine.net. Is there a way I can transfer all my wordpress posts into it? Any kind of help would be greatly appreciated!

Looking forward to reading more. Great post.Thanks Again. Fantastic.

Very interesting subject , thanks for posting.