Introduction

In the dynamic world of Lean management, Standard Work emerges as a cornerstone methodology, instrumental in establishing an efficient, transparent, and predictable workflow. It serves as the baseline from which continuous improvement efforts spring, ensuring that the gains from Lean initiatives are both sustainable and buildable.

History and Development

Standard Work, although now a fundamental aspect of Lean, finds its roots in the early industrial standardization practices. With the evolution of the Toyota Production System (TPS), it gained prominence as a systematic approach to optimizing workflows and minimizing waste. It has since become a key component of Lean methodologies worldwide.

Key Principles

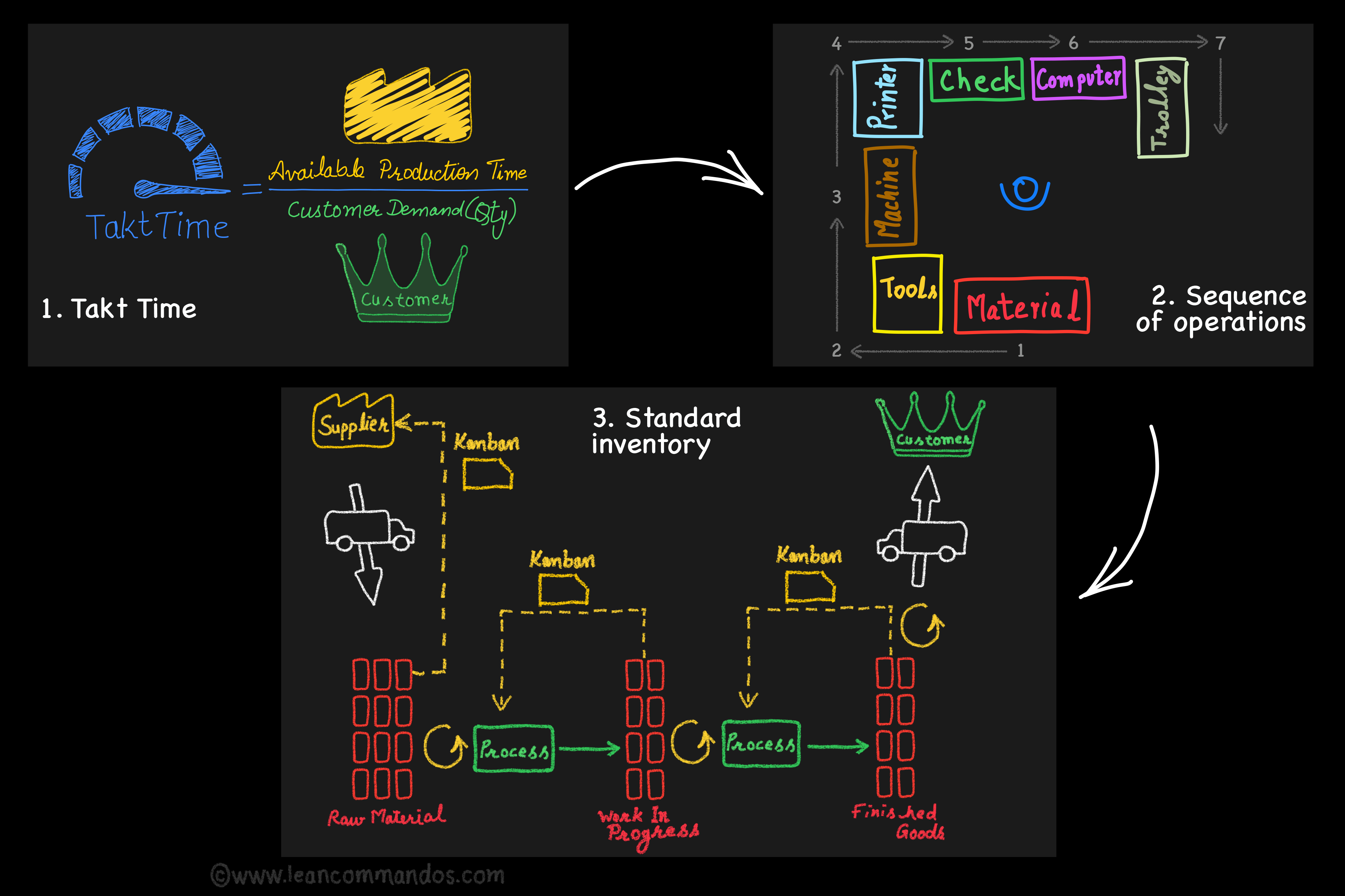

The core principles of Standard Work focus on three main elements: Takt Time, the sequence of operations, and the standard inventory. Takt Time aligns production with customer demand, ensuring each step of the process is timed to meet this demand without overproduction. The sequence of operations establishes the most efficient order of process steps, and the standard inventory defines the minimum amount of materials necessary to keep the process flowing smoothly.

When to Use the Tool

Standard Work is applicable in any repetitive process where there is a need to reduce variability, ensure quality, and optimize time and resources. It is particularly beneficial in manufacturing settings but is also increasingly applied in service and administrative workflows.

How It Works

Implementing Standard Work is a strategic process that involves meticulous documentation, analysis, and collaboration to optimize workflows effectively. Here’s an extended look at how Standard Work works and the steps involved in its implementation.

1. Documenting Current Best Practices:

The first step in implementing Standard Work is to thoroughly document the existing best practices within the workflow. This involves capturing every detail of the process, from the sequence of tasks to the tools and materials used at each step. Documentation can take various forms, such as written procedures, flowcharts, or even digital multimedia presentations, depending on the complexity of the process and the preferences of the team.

2. Timing and Analysis:

Once the current practices are documented, the next step is to time each step of the process. This involves measuring the time taken to complete individual tasks and recording any delays or bottlenecks encountered along the way. The data collected during this phase provides valuable insights into the efficiency of the workflow and identifies areas for improvement. Additionally, analyzing the workflow allows teams to identify waste, such as unnecessary movements, waiting times, or overproduction, which can be eliminated to streamline operations further.

3. Collaboration and Continuous Improvement:

A crucial aspect of implementing Standard Work is collaboration with the employees who perform the tasks on a daily basis. Their firsthand knowledge and experience are invaluable in accurately capturing the process and identifying opportunities for improvement. By involving frontline workers in the standardization process, organizations can ensure that the standards reflect the reality of the work environment and are more likely to be embraced by the team.

4. Standardization and Training:

Once the best practices are documented, analyzed, and refined through collaboration, the next step is to establish standardized work procedures based on the insights gained. Standardization involves defining the optimal sequence of operations, setting clear quality standards, and determining the appropriate inventory levels to support the workflow. These standardized procedures serve as the baseline for training new employees and ensuring consistency in performance across the organization.

5. Continuous Monitoring and Adaptation:

Implementing Standard Work is not a one-time event but an ongoing process of continuous improvement. Organizations must establish mechanisms for monitoring adherence to the standards and collecting feedback from frontline workers. Regular audits and reviews should be conducted to ensure that the standardized procedures are followed consistently and to identify any deviations or opportunities for further optimization. Additionally, organizations must remain flexible and agile, willing to adapt and refine the standards as new insights and best practices emerge

In summary, implementing Standard Work is a systematic process that involves documenting current practices, analyzing workflows, collaborating with employees, standardizing procedures, and continuously monitoring and adapting to drive efficiency and excellence in operations. By following these steps diligently and fostering a culture of continuous improvement, organizations can unlock the full potential of Standard Work and achieve sustainable success in their Lean journey.

Benefits

The adoption of Standard Work results in numerous benefits: a reduction in errors and rework, improved quality control, more predictable output, and enhanced employee training and engagement. It lays the groundwork for a culture of continuous improvement by providing a clear benchmark for measuring gains.

Common Mistakes and Pitfalls

Common pitfalls in implementing Standard Work include insufficient communication, failing to update standards as improvements are made, and not involving the employees who do the work in the standardization

Tips for Success

Successful implementation of Standard Work requires thorough training, regular audits, and a system for feedback and suggestions. Emphasizing the importance of standards and ensuring they are easily accessible and understandable to all employees are also critical steps. Flexibility to adapt and improve standards as new insights are gained is equally important.

Integration With Other Lean Tools

Standard Work synergizes with other Lean tools such as 5S for workplace organization, Kaizen for continuous improvement, and Kanban for inventory management. These tools complement Standard Work by creating an environment where efficiency is constantly being pursued and waste is minimized.

FAQs

How often should Standard Work be updated?

Standard Work should be reviewed and updated whenever there is a change in the process, introduction of new equipment, or after continuous improvement activities that result in a better way of working.

Can Standard Work be applied to creative or non-repetitive jobs?

While Standard Work is best suited for repetitive tasks, elements of it can be applied to less structured work to bring clarity and improve efficiency.

What is the difference between Standard Work and work instructions?

Work instructions are more detailed and can include information for troubleshooting and special cases, while Standard Work focuses on the routine for the normal flow of work.

How do you balance Standard Work with the need for flexibility?

Standard Work sets a baseline; however, it should allow for controlled flexibility to manage unexpected situations or to test improvements.

Is Standard Work sufficient on its own to manage processes?

While Standard Work is crucial, it is most effective when used in conjunction with other Lean tools and within the context of a broader Lean management system.

References and Further Reading

For those looking to dive deeper into Standard Work, the following books offer comprehensive insights:

- “Creating a Lean Culture: Tools to Sustain Lean Conversions” by David Mann.

- “The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer” by Jeffrey K. Liker.

- “Lean Thinking: Banish Waste and Create Wealth in Your Corporation” by James P. Womack and Daniel T. Jones.

Each of these works provides a unique perspective on how Standard Work fits within the larger Lean framework, offering strategies for implementation and case studies of successful application.

2 Responses

I conceive you have observed some very interesting points, thanks for the post.

Appreciate you sharing, great blog.Really thank you! Will read on…