Introduction

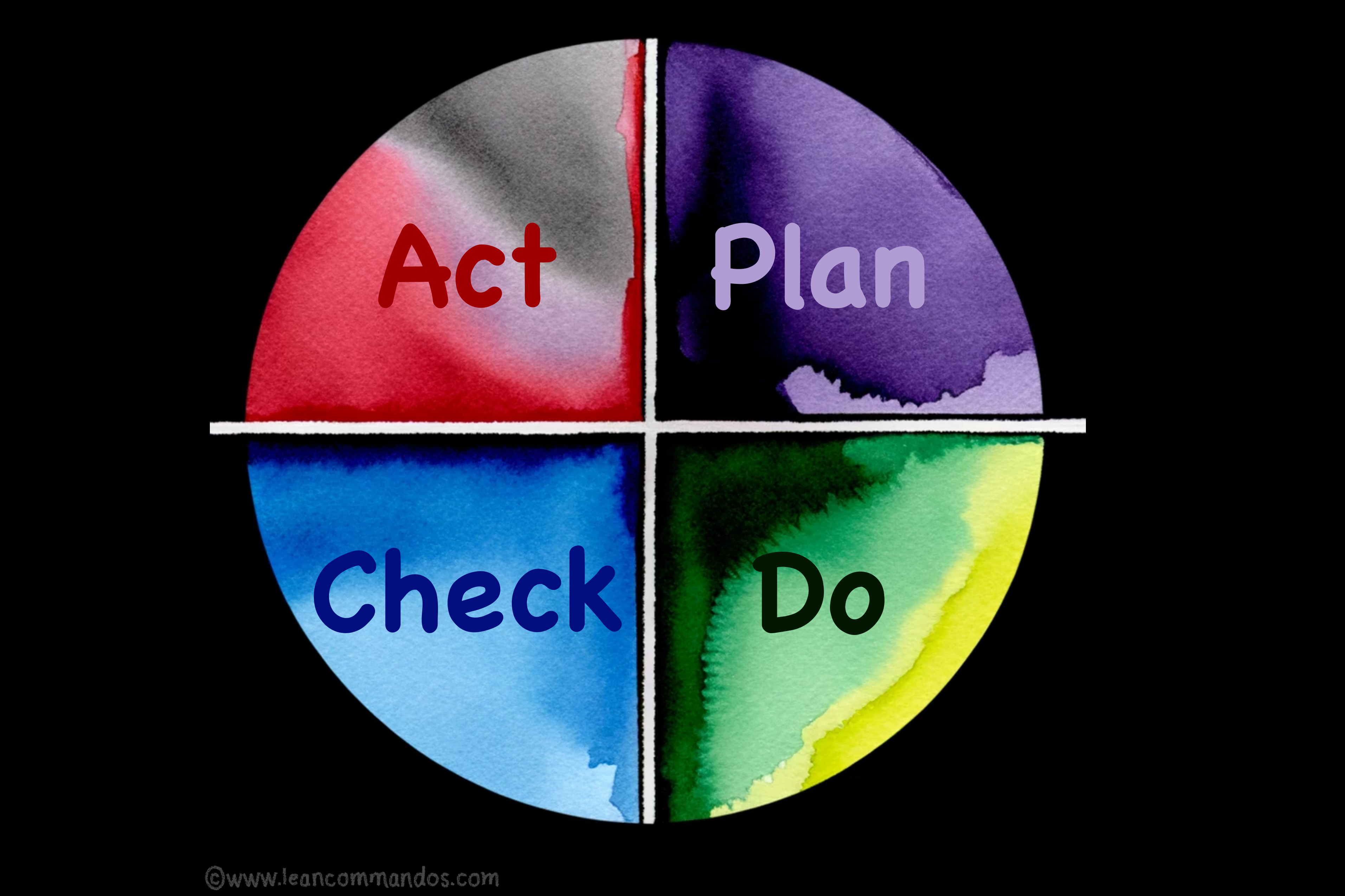

The Plan-Do-Check-Act (PDCA) cycle is a cornerstone of Lean Management, propelling continuous improvement in processes across industries. Its simplicity and effectiveness have cemented PDCA as a favorite among Lean tools, guiding teams to achieve incremental enhancements in quality and efficiency.

History and Development

Originating from the work of Dr. William Edwards Deming, the PDCA cycle has been a foundational element in quality management disciplines since the mid-20th century. Initially termed the “Shewhart cycle”, PDCA became a central theme in Deming’s teachings and is often referred to as the “Deming Wheel” in his honor.

Key Principles

The PDCA cycle is predicated on four iterative steps:

- Plan: Identify an opportunity and plan for change.

- Do: Implement the change on a small scale.

- Check: Use data to analyze the results of the change and determine whether it made a

difference. - Act: If the change was successful, implement it on a wider scale and continuously assess

your results. If the change did not work, begin the cycle again.

When to Use the Tool

PDCA is versatile and can be employed for any process improvement initiative. It is particularly useful for addressing complex systemic issues where the solutions are not immediately apparent and for instigating change when more information is needed before a full-scale implementation.

How It Works

The Plan-Do-Check-Act (PDCA) cycle is a systematic approach designed to foster continuous improvement within processes. This methodical framework guides organizations through a series of iterative steps, enabling them to identify opportunities, implement changes, evaluate outcomes, and refine strategies for ongoing enhancement.

The PDCA cycle initiates with the planning phase, a critical step where clear objectives are established, and processes are meticulously defined. During this stage, teams analyze current practices, identify areas for improvement, and develop strategies to address them. This phase lays the groundwork for subsequent actions and sets the direction for change initiatives.

Following the planning phase is the execution stage, known as the ‘Do’ phase. Here, organizations put their plans into action on a small, manageable scale. By implementing changes incrementally, teams can minimize disruption to operations while gaining valuable insights into the effectiveness of proposed solutions. This phase serves as a testing ground, allowing organizations to assess the practicality and viability of their improvement efforts in a controlled environment.

Once changes have been implemented, the ‘Check’ phase comes into play. This step involves rigorously evaluating the outcomes against predefined metrics and objectives. Data analysis is crucial during this phase, as it provides insights into the impact of the implemented changes and helps determine whether they have achieved the desired results. By comparing actual performance with expected outcomes, organizations can identify discrepancies, uncover root causes of inefficiencies, and make informed decisions about the next course of action.

The final stage of the PDCA cycle is the ‘Act’ phase, where organizations take decisive action based on the findings from the previous steps. If the implemented changes are deemed successful, they are standardized and integrated into broader processes. Continuous monitoring and refinement are essential during this phase to ensure that improvements are sustained over time. Conversely, if the changes do not yield the desired results, organizations must revisit the planning phase, adjust their approach, and initiate the cycle anew. This adaptive approach allows for ongoing optimization and ensures that organizations remain agile in response to evolving challenges and opportunities.

Overall, the PDCA cycle offers a structured framework for driving continuous improvement and fostering a culture of innovation within organizations. By systematically planning, executing, evaluating, and adjusting their strategies, businesses can achieve incremental enhancements in quality, efficiency, and overall performance. This iterative process not only drives short-term gains but also lays the foundation for long-term success and sustainability in today’s dynamic business landscape.

Benefits

PDCA encourages a culture of disciplined experimentation and learning. It minimizes the risk associated with change by testing in small increments. Moreover, it fosters an environment of continuous feedback, allowing for quick adjustments and informed decision-making.

Case Studies/Examples

A notable example of PDCA in action is its application at Toyota, where the cycle was implemented to reduce inventory waste. By planning targeted improvements, testing them in controlled environments, analyzing results, and acting based on findings, Toyota was able to significantly streamline its operations and reduce costs.

Common Mistakes and Pitfalls

One common mistake in employing PDCA is bypassing stages, often overlooking the ‘Check’ phase, leading to uninformed or premature actions. Another is resistance to reverting to the ‘Plan’ phase when a test fails, resulting in the repetition of flawed processes.

Tips for Success

- Be patient and allow each phase its due time.

- Embrace failures as learning opportunities.

- Ensure accurate data collection during the ‘Check’ phase.

- Involve all stakeholders in every phase for diverse perspectives.

Integration With Other Lean Tools

PDCA works well when combined with tools like 5S for workplace organization, Value Stream Mapping for process visualization, and Root Cause Analysis for in-depth problem-solving, creating a robust framework for Lean management.

FAQs

How often should the PDCA cycle be repeated?

PDCA is a continuous cycle and should be repeated as often as needed to achieve and maintain improvements.

Can PDCA be used for large-scale changes?

Yes, but it’s advisable to start with small, controlled experiments before scaling up.

Is PDCA suitable for non-manufacturing environments?

Absolutely. PDCA is versatile and can be applied to any industry or process.

How do we measure success in the ‘Check’ phase?

Success is measured against the objectives set in the ‘Plan’ phase, using quantitative and qualitative data.

How does PDCA relate to the Lean concept of ‘Kaizen’?

PDCA is a driving force behind Kaizen, which focuses on continuous, incremental improvements.

References and Further Reading

- “The New Economics for Industry, Government, Education” by W. Edwards Deming

- “Lean Thinking: Banish Waste and Create Wealth in Your Corporation” by James P. Womack and Daniel T. Jones

- “Toyota Kata: Managing People for Improvement, Adaptiveness, and Superior Results” by Mike Rother

By employing the PDCA cycle diligently, businesses can create a virtuous cycle of improvement, ensuring that Lean management principles not only take root but flourish, leading to sustainable growth and efficiency.

3 Responses

I am curious to find out what blog platform you have been using? I’m having some small security problems with my latest website and I would like to find something more secure. Do you have any solutions?

Thanks for the blog post, can I set it up so I get an email every time there is a new update?

You should take part in a contest for one of the best blogs on the web. I will recommend this site!