Introduction

Leader Standard Work (LSW) stands as a cornerstone in the realm of Lean management, offering a systematic approach to ensure operational excellence. At its core, LSW empowers leaders to set the standard for efficiency, productivity, and quality within their organizations. By integrating LSW into their practices, businesses can streamline operations, enhance communication, and foster a culture of continuous improvement

History and Development

Born out of the Toyota Production System (TPS) in the mid-20th century, Leader Standard Work has since evolved into a fundamental Lean tool. Initially utilized to maintain consistency in manufacturing processes, its application has transcended industries, finding relevance in service sectors, healthcare, and beyond. Through continuous refinement, LSW has become synonymous with Lean principles, embodying the commitment to eliminating waste and optimizing resources.

Key Principles

The essence of Leader Standard Work revolves around three key principles: standardization, accountability, and continuous improvement. By establishing standardized processes and routines, leaders create a framework for consistency and efficiency. Moreover, LSW instills a sense of accountability among team members, fostering a culture of ownership and responsibility. Through regular review and refinement, leaders drive continuous improvement, ensuring that standards evolve in tandem with organizational goals.

When to Use the Tool

Leader Standard Work proves invaluable in scenarios where organizations strive for operational excellence and sustainable growth. It is particularly effective in environments characterized by complex processes, diverse teams, and dynamic customer demands. Whether in manufacturing, service delivery, or administrative functions, LSW serves as a guiding light for leaders navigating the complexities of modern business operations.

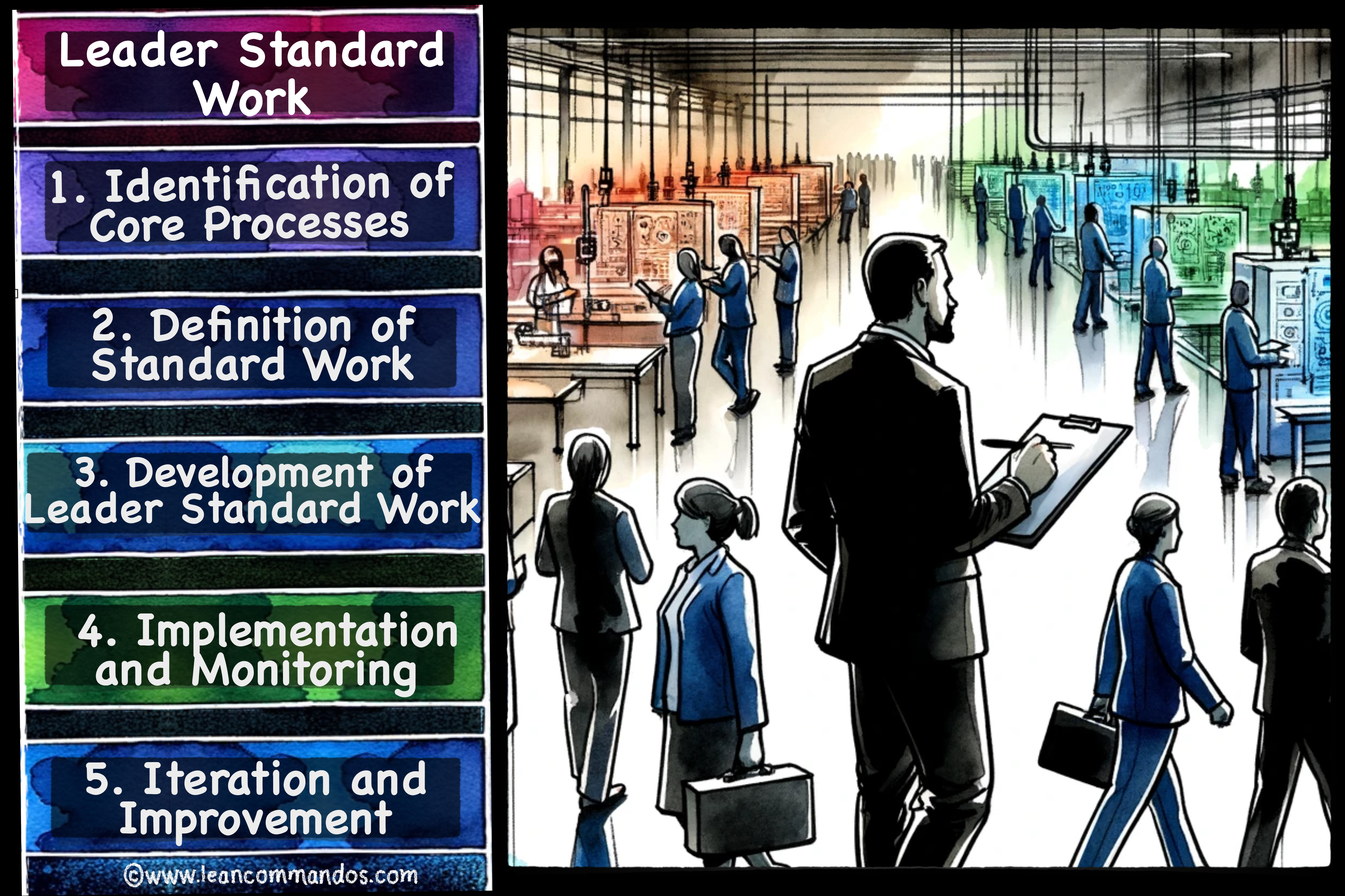

How It Works

Leader Standard Work (LSW) serves as a fundamental pillar in the realm of Lean management, facilitating operational excellence through a systematic and disciplined approach. At its core, LSW empowers leaders to set the standard for efficiency, productivity, and quality within their organizations. This section delves deeper into the workings of LSW, elucidating its significance and providing a comprehensive guide to its implementation.

1. Identification of Core Processes

The journey towards implementing Leader Standard Work begins with the identification of core processes that drive organizational success. This entails a thorough analysis of workflows, from frontline operations to strategic decision-making processes. By discerning the critical components of these processes, leaders can effectively prioritize areas for improvement and optimization.

2. Definition of Standard Work

Once core processes are identified, the next step involves the meticulous definition of standard work procedures. This entails establishing clear and concise standards for each process, encompassing key tasks, responsibilities, and performance metrics. Standardization serves as the cornerstone of LSW, providing a framework for consistency and efficiency across all levels of the organization.

3. Development of Leader Standard Work

Leadership plays a pivotal role in driving the adoption and adherence to standard work procedures. As such, leaders must define their own standard work routines, tailored to their roles and responsibilities within the organization. This may include activities such as gemba walks, process audits, team coaching, and performance reviews. By actively engaging in these tasks, leaders demonstrate their commitment to operational excellence and continuous improvement.

4. Implementation and Monitoring

The successful implementation of LSW hinges on the effective dissemination of standard work procedures across the organization. Leaders must roll out LSW initiatives systematically, ensuring that team members are adequately trained and equipped to adhere to established standards. Regular monitoring and feedback mechanisms are essential to gauge adherence to standards and identify areas for improvement.

5. Iteration and Improvement

Continuous improvement lies at the heart of Lean management philosophy, and LSW is no exception. Leaders must embrace a mindset of perpetual refinement, continuously evaluating and updating standard work procedures based on feedback, changing circumstances, and evolving organizational needs. This iterative process ensures that LSW remains relevant and effective in driving operational excellence over time.

In conclusion, Leader Standard Work stands as a powerful tool for driving operational excellence and fostering a culture of continuous improvement within organizations. By adhering to standardized routines and embracing a mindset of perpetual refinement, leaders can propel their organizations towards sustainable success in today’s dynamic business landscape.

Benefits

- Enhanced Operational Efficiency

- Improved Communication and Collaboration

- Heightened Employee Engagement and Accountability

- Accelerated Problem-Solving and Decision-Making

- Sustainable Continuous Improvement Culture

Common Mistakes and Pitfalls

- Lack of Leadership Commitment: Without strong leadership buy-in, LSW initiatives are bound to falter.

- Overly Prescriptive Standards: Rigidity in standardization can stifle innovation and creativity.

- Inadequate Training and Support: Without proper training, employees may struggle to understand and adhere to LSW protocols.

- Failure to Adapt: Organizations must be agile in their approach, adapting LSW to meet changing business dynamics.

- Ignoring Employee Feedback: Leaders must actively seek and incorporate feedback from frontline employees to ensure the relevance and effectiveness of LSW.

Tips for Success

Foster a Culture of Continuous Improvement

- Foster a Culture of Continuous Improvement

- Invest in Leadership Development and Training

- Leverage Technology to Enhance Visibility and Accountability

- Empower Frontline Employees to Drive Change

- Regularly Review and Update Standard Work Procedures

Integration With Other Lean Tools

Leader Standard Work synergizes seamlessly with other Lean methodologies such as 5S, Kaizen, and

Value Stream Mapping. By integrating LSW into broader Lean initiatives, organizations can amplify their

impact and drive holistic transformation across the value chain.

FAQs

What is Leader Standard Work (LSW)?

Leader Standard Work is a Lean management tool that outlines the standard tasks and responsibilities of leaders within an organization, ensuring consistency, accountability, and continuous improvement

How does LSW differ from standard work?

While standard work focuses on frontline processes, Leader Standard Work applies to leaders, defining their routines and responsibilities in driving operational excellence.

How often should Leader Standard Work be reviewed?

LSW should be reviewed regularly to ensure alignment with organizational goals and evolving business needs. Quarterly or semi-annual reviews are common practice.

Can Leader Standard Work be applied in non-manufacturing environments?

Yes, Leader Standard Work is applicable across industries, including service sectors, healthcare, and administrative functions, wherever leadership plays a critical role in process performance.

What role does technology play in supporting LSW implementation?

Technology can facilitate LSW implementation by providing tools for task management, performance tracking, and real-time communication, enhancing visibility and accountability.

Conclusion

Leader Standard Work epitomizes the essence of Lean management, empowering leaders to drive operational excellence and foster a culture of continuous improvement. By adhering to standardized routines, leaders set the benchmark for efficiency, accountability, and innovation, propelling organizations towards sustainable success in an ever-evolving business landscape.

References and Further Reading

- “Lean Thinking: Banish Waste and Create Wealth in Your Corporation” by James P. Womack and Daniel T. Jones

- “The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer” by Jeffrey K. Liker

- “Creating a Lean Culture: Tools to Sustain Lean Conversions” by David Mann

3 Responses

Some genuinely excellent articles on this internet site, appreciate it for contribution.

Very good article post.Really thank you! Want more.

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.