KPIs

Introduction Key Performance Indicators (KPIs) are the beacon lights for any organization that steers the workforce towards achieving strategic goals. These quantifiable measures assess the success of an organization in terms of progress against its objectives. Whether it’s boosting sales, improving customer satisfaction, or enhancing operational efficiency, KPIs are integral in the lean management toolkit […]

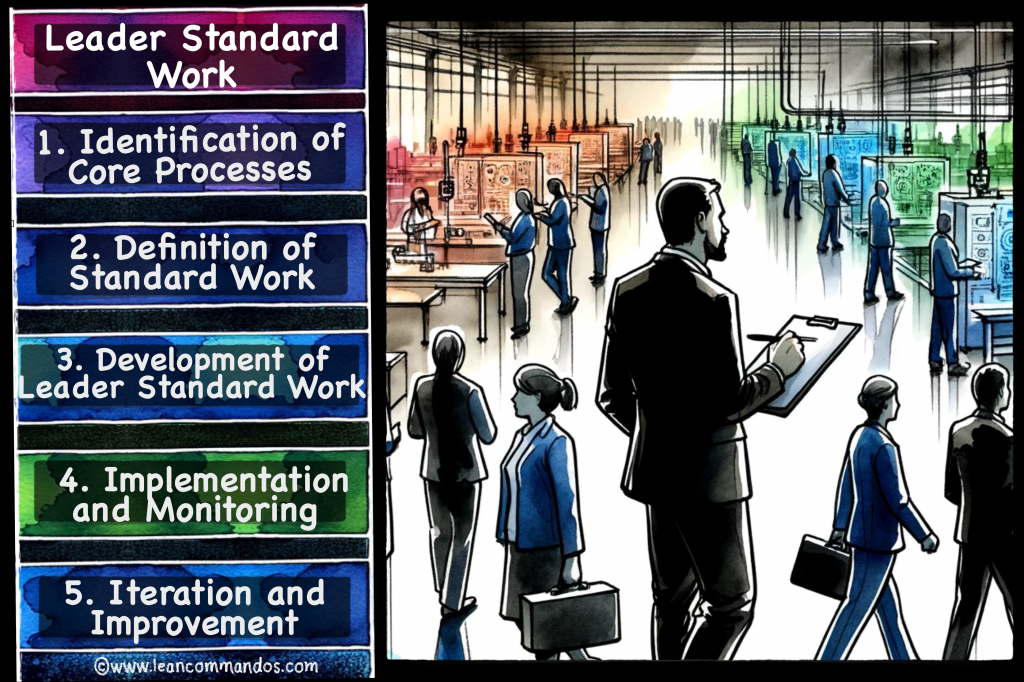

Leader Standard Work

Introduction Leader Standard Work (LSW) stands as a cornerstone in the realm of Lean management, offering a systematic approach to ensure operational excellence. At its core, LSW empowers leaders to set the standard for efficiency, productivity, and quality within their organizations. By integrating LSW into their practices, businesses can streamline operations, enhance communication, and foster […]

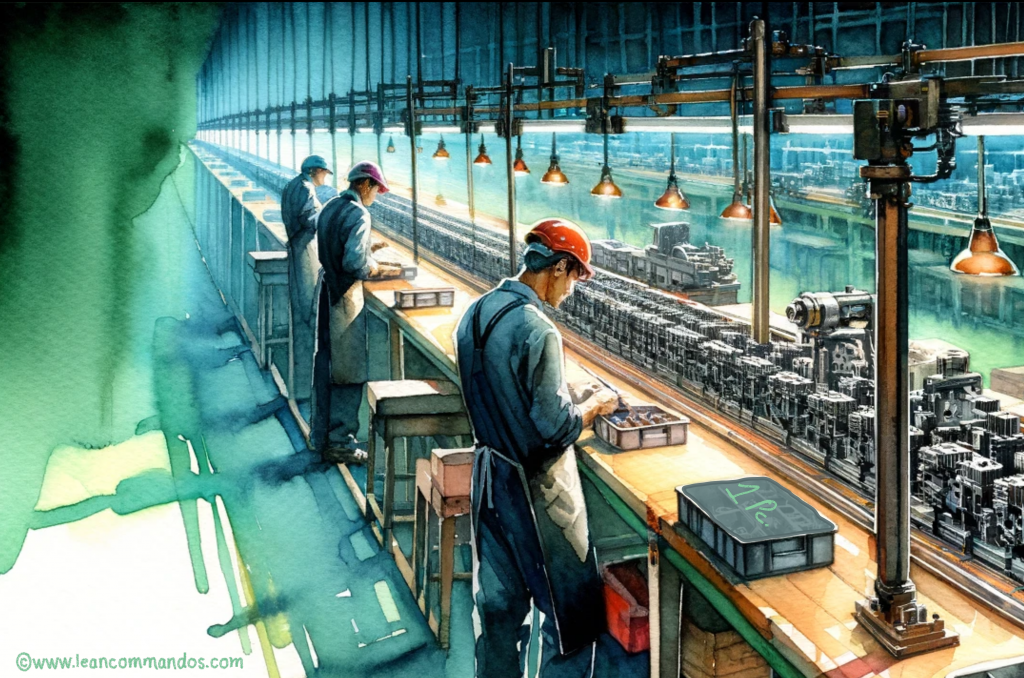

One Piece Flow

Introduction One Piece Flow, a cornerstone of Lean manufacturing, focuses on the flow of products through the production process one at a time, minimizing work in progress (WIP) and enabling a smoother production system. This approach contrasts with traditional batch processing, where products are manufactured in large groups, leading to longer lead times and higher […]

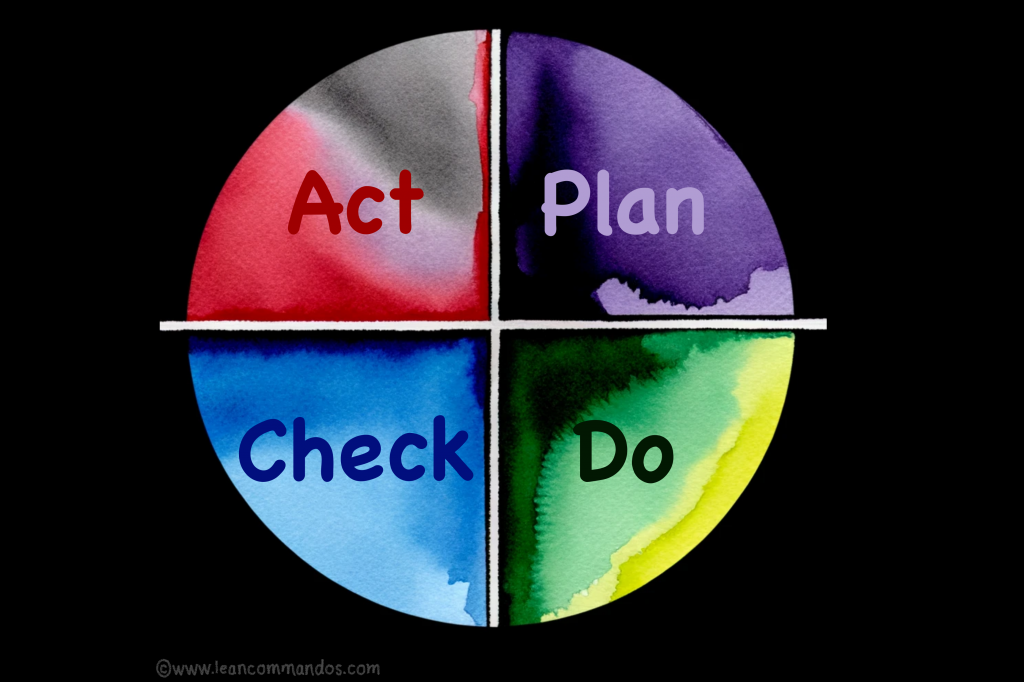

PDCA

Introduction The Plan-Do-Check-Act (PDCA) cycle is a cornerstone of Lean Management, propelling continuous improvement in processes across industries. Its simplicity and effectiveness have cemented PDCA as a favorite among Lean tools, guiding teams to achieve incremental enhancements in quality and efficiency. History and Development Originating from the work of Dr. William Edwards Deming, the PDCA […]

Quality Circles

Introduction processes, enhancing productivity, and fostering a culture of continuous improvement. As a fundamental Lean tool, Quality Circles enable organizations to harness the collective intelligence of their workforce to identify and solve problems efficiently. History and Development The concept of Quality Circles originated in Japan during the 1960s, primarily through the efforts of Dr. Kaoru […]

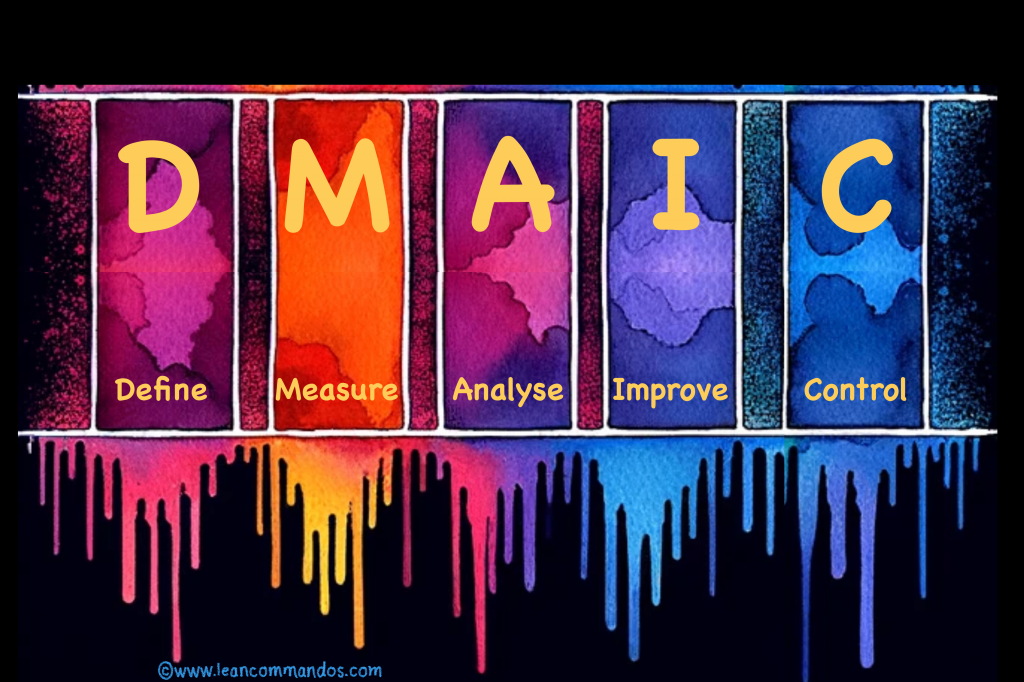

Six Sigma

Introduction Six Sigma is a powerful Lean management tool designed to minimize defects, enhance efficiency, and optimize processes across various industries. Its primary purpose lies in streamlining operations, reducing waste, and ultimately enhancing customer satisfaction. History and Development Originating from Motorola in the 1980s, Six Sigma has evolved into a comprehensive methodology embraced by organizations […]

Standard Work

Introduction In the dynamic world of Lean management, Standard Work emerges as a cornerstone methodology, instrumental in establishing an efficient, transparent, and predictable workflow. It serves as the baseline from which continuous improvement efforts spring, ensuring that the gains from Lean initiatives are both sustainable and buildable. History and Development Standard Work, although now a […]

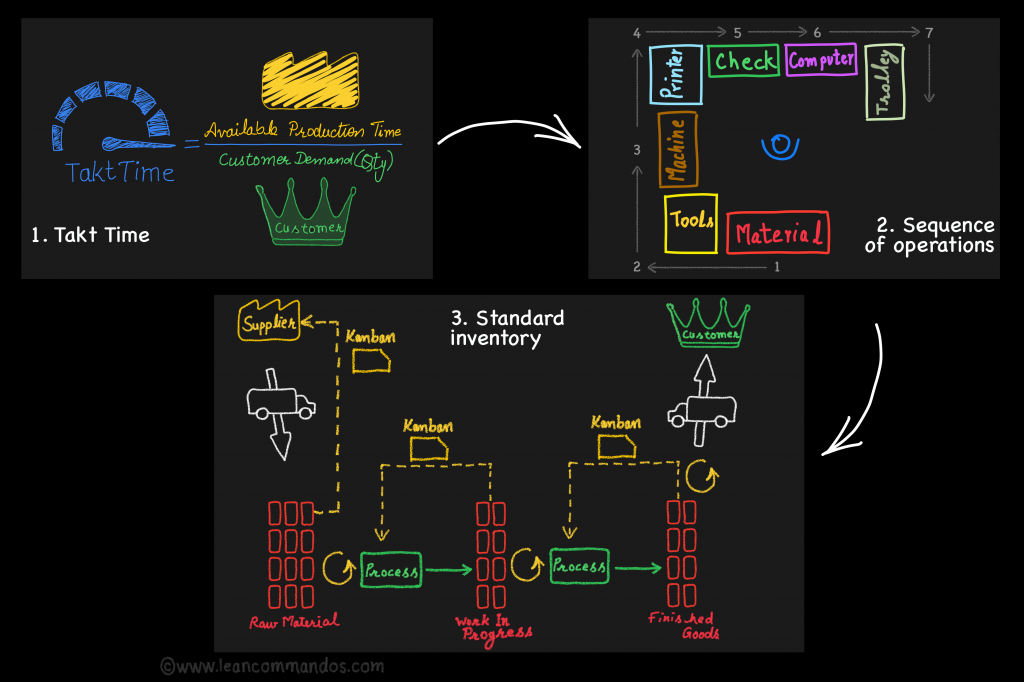

Takt Time

Introduction In the realm of Lean management, Takt Time stands as a critical measure that aligns production with customer demand. Derived from the German word ‘Takt,’ which means ‘beat’ or ‘meter,’ it fundamentally represents the rhythm or pulse at which products must be created to meet customer needs without accumulating excess inventory. History and Development […]

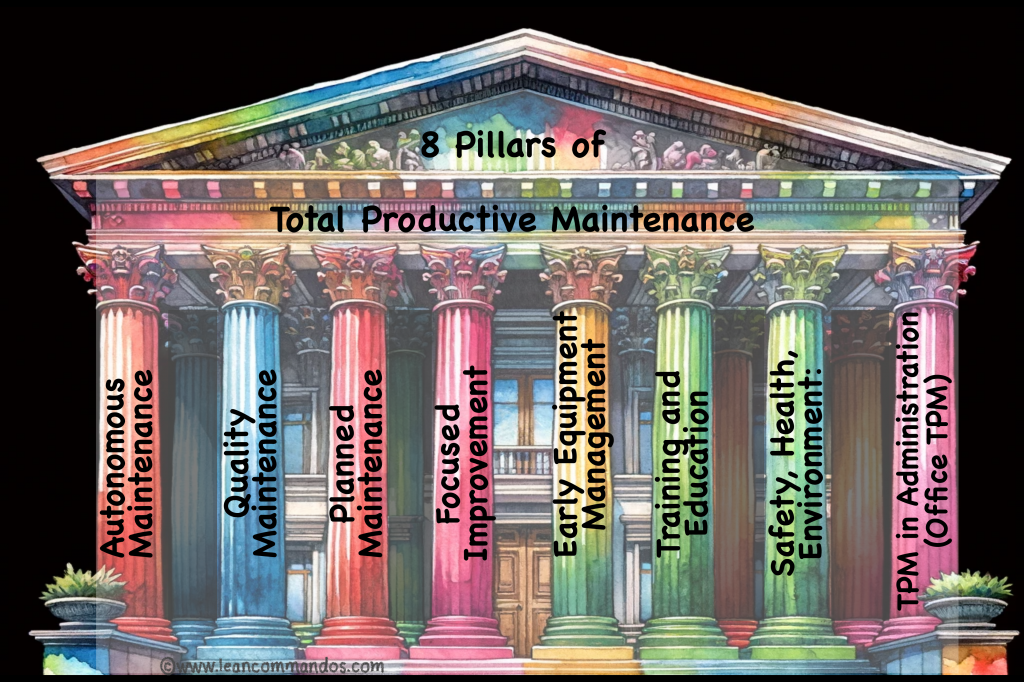

TPM

Introduction Total Productive Maintenance (TPM) stands out as a pivotal Lean tool designed to optimize equipment effectiveness. By integrating maintenance into the daily operations of all employees, TPM transcends traditional maintenance boundaries, fostering a proactive culture aimed at preventing breakdowns and maximizing productivity. History and Development Tracing its roots to post-war Japanese industry, TPM was […]

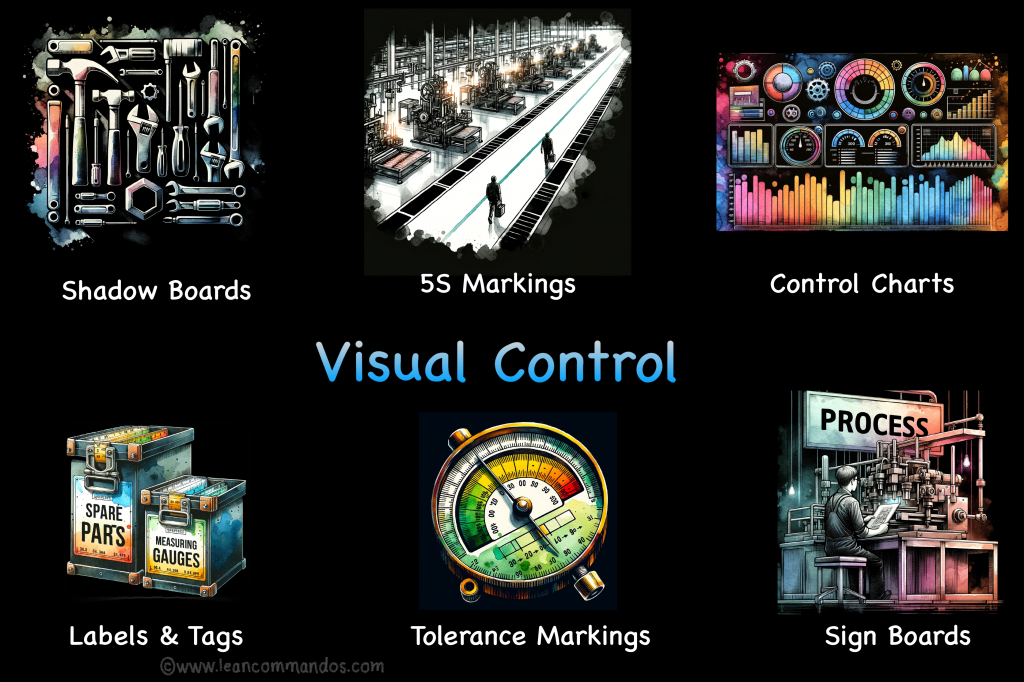

5S

Introduction In the world of Lean management, 5S stands as a beacon of efficiency, a systematic approach to workplace organization that lays the groundwork for continuous improvement. This tool is not merely about cleanliness or organization; it is a pathway to transforming the culture of work environments, driving efficiency, safety, and a deep-seated operational excellence. […]